Acbee – Smart Warehouse Management System

SmartWMS

Smart Warehouse Management System

SmartWMS is a professional warehouse management system developed by Acbee.

It is dedicated to helping enterprises solve various warehouse management challenges,

achieving refined, standardized, and intelligent warehouse management.

SmartWMS offers intelligent, standardized, and efficient warehouse management solutions to optimize operations and enhance accuracy.

Features

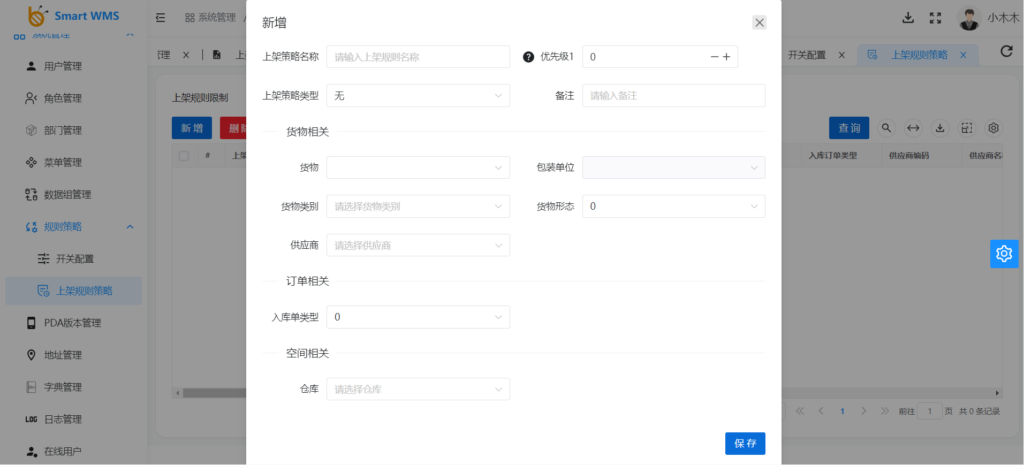

Multi-dimensional and Flexible Rule Strategies

Supports rapid adjustment of operational workflows and inventory strategies, enhancing supply chain responsiveness and flexibility.

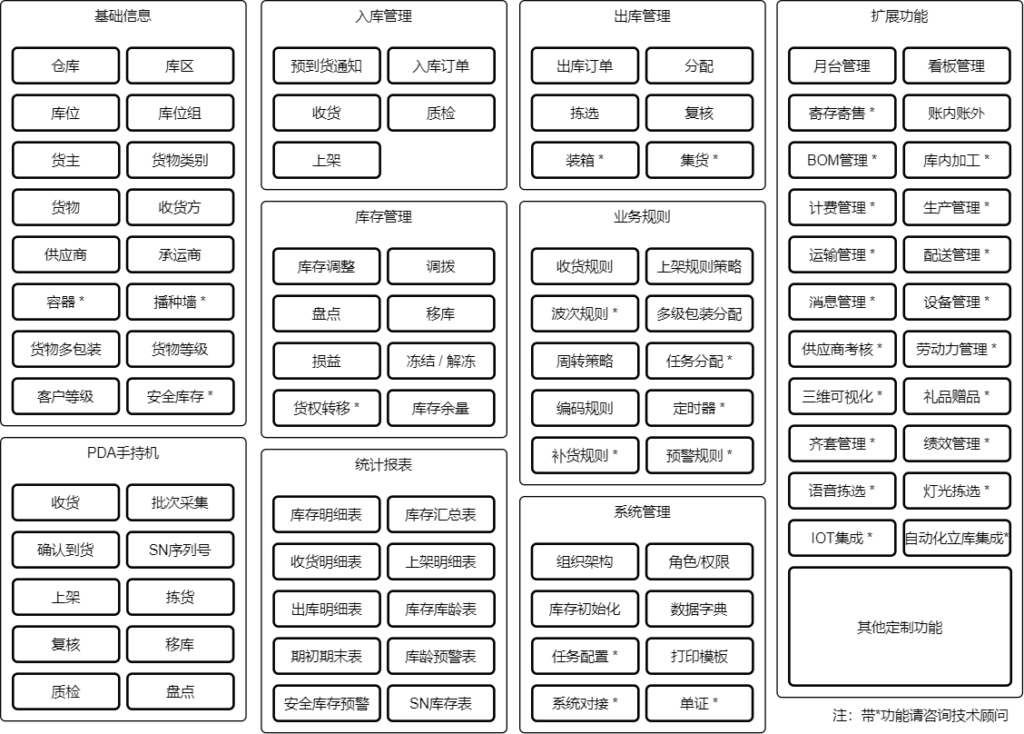

Rich and Practical Functional Modules

Covers common business scenarios, offering solutions that combine standardization with customization.

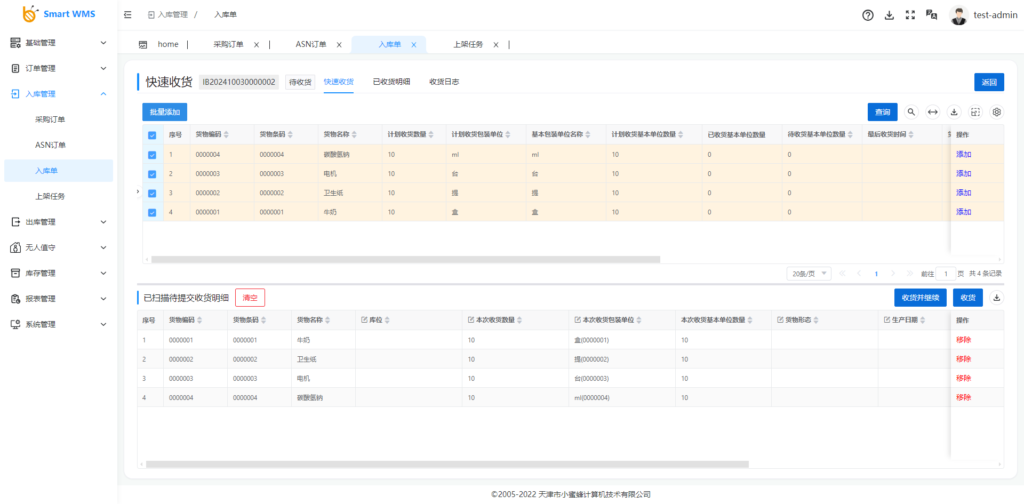

Simple and Clear User Interface

Easy-to-use system that imposes no additional burden, reducing human errors caused by complex or confusing interfaces.

SmartWMS provides comprehensive functionality—including flexible rule configuration, modular applications, and an intuitive interface—to streamline warehouse operations and support efficient, error-free management.

Utilities

Unattended Warehouse model

Self-Service Material Withdrawal

What is the Unattended Warehouse Model?

The Unattended Warehouse Model refers to a warehouse operation mode that requires no on-site staff, enabling material requesters to independently withdraw materials. By leveraging IoT and facial recognition technology, and powered by SmartWMS, material requesters can complete the entire withdrawal process without assistance from warehouse personnel. Following system-guided workflows, they gain access via facial recognition, print picking lists, pick items, and perform self-checkout—all autonomously.

Unattended Material Withdrawal Process

- Withdrawal Request Submission and Approval: The requesting department submits a material withdrawal request through the SmartWMS system, which is then sent to the supervising department for approval.

- Access Control Verification: The access system identifies and verifies the requester’s identity, granting entry to the warehouse.

- Self-Service Withdrawal: Supports multiple withdrawal methods (paper-based picking, PDA barcode scanning, PTL light-directed picking, AGV goods-to-person picking, automated storage and retrieval systems, etc.).

- Verification: The requester returns to the workstation, logs into the system, and completes the verification process.

Multi-Owner + Multi-Warehouse

Multi-Owner + Multi-Warehouse

What is Multi-Owner?

“Multi-Owner” refers to managing goods belonging to multiple different owners within a single physical warehouse. Ownership of the goods may belong to suppliers, retailers, manufacturers, or any entity holding title to the inventory. Each owner may have distinct inventory management needs and operational processes.

– Supports different owners for the same product.

– Allows customized rule configurations for different owners based on their specific management requirements.

– Supports transfer of ownership rights.

What is Multi-Warehouse?

“Multi-Warehouse” means the system can simultaneously manage one or more warehouses located in different geographical locations.

- Supports corporate group structures.*

- Enables customized business rules for different warehouses or even different zones within the same warehouse, configurable down to the individual storage bin level.

- Supports inter-warehouse transfer operations.

For details on features marked with *, please consult a technical advisor.

CASES

Industries Served

Manufacturing | Spare Parts & Components | 3C Electronics | Logistics & Transportation | Food & Beverage | Agricultural Products | Tobacco Products | Military Supplies

SOLUTIONS

Solutions

- Delivering significant value across various industries.

- Empowering numerous enterprises to achieve refined and intelligent warehouse operations.

- Significantly improving inventory accuracy, operational efficiency, and overall supply chain performance.

SERVICES

Service Process

Pre-Sales

Business Consultation: Engage in in-depth discussions with clients through remote meetings, on-site surveys, and other methods to fully understand their business needs, pain points, and objectives.

Product Demonstration: Showcase the features and capabilities of our mature product to help clients recognize its potential value.

Requirements Analysis: Based on consultation and demonstration feedback, analyze client requirements, propose tailored solutions, and clarify customization needs and project goals.

During Sales

Custom Development: Conduct customized development based on standard products according to the results of requirements analysis, ensuring specific client needs are met.

Testing & Validation: Perform thorough testing of customized functionalities to verify they meet client expectations, ensuring system stability and compatibility.

Deployment & Implementation: Deploy the developed software into the client’s environment, complete system configuration and data initialization, and ensure a smooth go-live process.

Post-Sales

Training & Support: Provide comprehensive training and ongoing technical support to ensure clients can effectively operate and maintain the system.

Acceptance & Optimization: Verify that the system meets all agreed requirements. After formal acceptance, continuously collect user feedback and implement system optimizations to maximize customer satisfaction.

Documentation Delivery: Prepare and deliver user manuals and technical documentation to help clients understand and use the system correctly.

PRICING

Pricing Structure

Standard Product

For details, please consult a technical advisor.

Optional Add-ons & Customization

For details, please consult a technical advisor.

Hardware Integration

For details, please consult a technical advisor.

Implementation & Training

Remote implementation and training: Free of charge.

On-site implementation and training: Starting from 1,500 CNY per person per day, plus travel and accommodation expenses.

After-Sales Service

Remote support: First year free; 15% of contract value per year thereafter.

On-site support: Starting from 1,500 CNY per person per day, plus travel and accommodation expenses.

Contact Us: Phone/WeChat: 13022223322

faq

Frequently Asked Questions

Q: Does SmartWMS support multi-warehouse management?

A: Yes, SmartWMS supports multi-warehouse management.

Q: We currently communicate with suppliers offline when purchasing materials. What options are available in SmartWMS to improve supplier collaboration?

A: Yes, SmartWMS supports supplier collaboration through features such as delivery appointment scheduling and supplier performance evaluation.

Supplier Evaluation:

Track and analyze key performance metrics including on-time delivery compliance and quality inspection results.

Supplier Management & Collaboration Process:

SmartWMS can integrate with external systems (e.g., ERP) to import purchase orders.

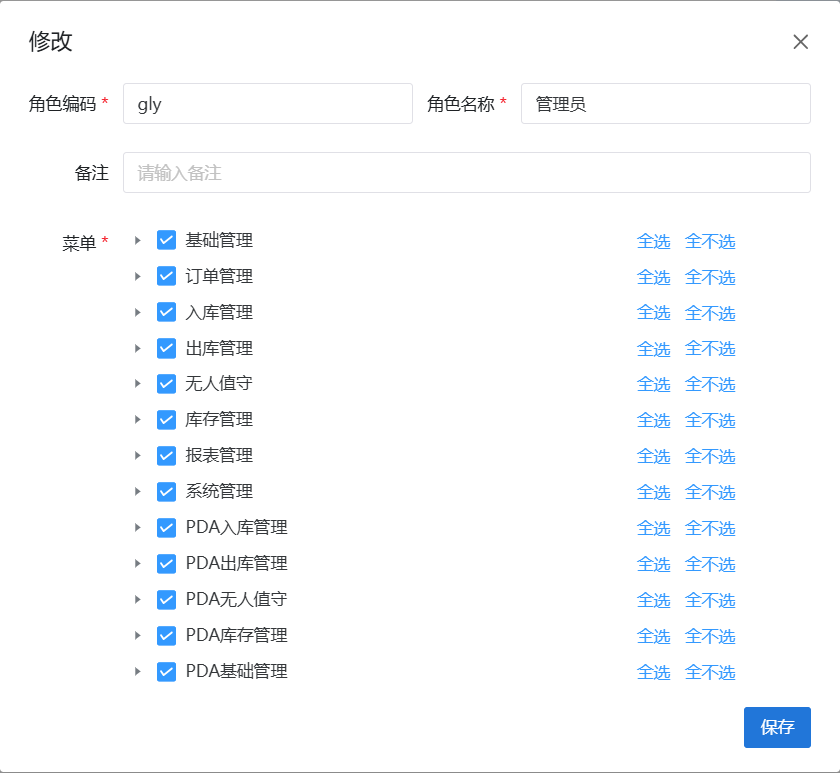

Assign dedicated WMS accounts and role-based permissions to suppliers.

Suppliers log in to SmartWMS to schedule deliveries, specifying details such as delivery time, driver information, and contact person.

Enforce standardized packaging and labeling requirements through the system.

Warehouse staff review and approve delivery appointments.

Upon arrival, gate personnel verify the Advanced Shipping Notice (ASN) to grant access, then record actual arrival time, loading dock, and vehicle information.

Quality inspection results for supplier goods are documented in the system.

This streamlined process enhances transparency, reduces errors, and improves coordination between your warehouse and suppliers.

Q: When allocating inventory for outbound orders, some items require FIFO (First-In, First-Out) allocation, while others need to be allocated by batch number. Can the WMS support this?

A: Yes. SmartWMS supports configuring different inventory allocation strategies per item. The system calculates available inventory based on strategy priority, including:

Batch number sequencing

Receipt date (FIFO) sequencing

Remaining shelf life sequencing

Lane balancing allocation

Clearance-first priority

Efficiency-first priority

These allocation strategies can be set according to various dimensions, including: warehouse, owner, product category, product grade, outbound order type, customer, customer tier, and storage zone.

Q: How is safety stock managed in SmartWMS?

A: SmartWMS provides intelligent safety stock management by allowing users to set multi-dimensional threshold conditions for stock level alerts. When inventory falls below the defined safety level, the system can automatically trigger corresponding tasks such as replenishment or purchase requests, based on predefined configurations.

Alerts can be delivered through multiple notification methods, including:

Email

SMS

DingTalk

Enterprise WeChat

The safety stock rules can be configured at various levels, including:

Item

Product category

Warehouse

Owner

Supplier

Storage zone

This flexible approach ensures timely inventory replenishment and helps maintain optimal stock levels across diverse operational scenarios.

Latest Articles

-

中标丨SmartWMS中标某高端防伪企业智慧仓储管理系统项目

近日,SmartWMS成功中标某高端防伪企业智慧仓储管理系统项目。这标志着SmartWMS在智能仓储与高端防伪行业的仓储数字化解决方案领域再获重要认可。关于SmartWMS:SmartWMS(智慧仓储管理系统)是小蜜蜂公司旗下拥有自主知识产权的业界领先产品。深耕仓储管理领域15年,我们始终致力于研发兼具卓越用户体验与强大功能的WMS系统,并通过创新技术赋能企业,驱动仓储物流的数字化与智能化升级,最终优化供应链整体效率。

-

签约丨SmartWMS签约中国天辰工程公司,助力陕西有色天宏多晶硅产业升级项目智慧仓储建设

近日,SmartWMS与中国化学工程集团旗下骨干企业——中国天辰工程有限公司正式签署合作协议。SmartWMS将为“陕西有色天宏瑞科硅材料有限责任公司8万吨电子级粒状多晶硅产业升级项目(第一步2.5万吨项目)装置工程总承包(EPC)项目”提供其核心产品 《智慧仓储管理系统5.0》及相关服务,服务该项目建设期的仓储管理需求。 在该大型高科技材料EPC项目中,中国天辰工程公司作为总承包方,肩负项目建设重任。SmartWMS将深度融入项目建设过程,为项目关键建设期提供专业、高效的仓储管理系统支撑。部署的SmartWMS 5.0系统,凭借其智能作业调度、精细库存管控、全流程可视化与高效协同等核心优势,将显著提升项目现场物资管理的精准度与流转效率,有效保障大型工程物资的有序供应与成本优化,为项目的高质量、按进度推进奠定坚实的物资管理基础。 此次合作标志着SmartWMS在高端制造业及大型EPC工程智慧仓储管理领域的实力再获重量级认可。SmartWMS将充分发挥自身技术优势与实践经验,携手中国天辰工程公司,全力保障陕西有色天宏这一重大产业升级项目的成功建设,共同推动我国电子级多晶硅产业向智能化、数字化转型迈出坚实一步。

-

小蜜蜂WMS签约东南亚工业园智慧仓储建设项目

近日,小蜜蜂WMS正式签约东南亚某工业园智慧仓储建设项目,为园区提供智能化仓储解决方案。此次合作标志着中国智慧仓储物流技术在国际产业园区建设中的深度应用。系统建成后,将显著提升园区物资周转效率,降低存储成本,为园区物资“精准管控、降本增效”的管理目标提供技术保障。